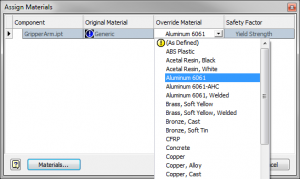

Assign a Material

- On the Analysis tab Material panel, click Assign .

- In the Assign Materials dialog box, Override Material column, click the drop-list and select the material you wish to use.

- In the Safety Factor column, select Yield Strength or Ultimate Tensile Strength. These strengths will be used in safety factor calculations if you perform a Stress Analysis.

- Click OK

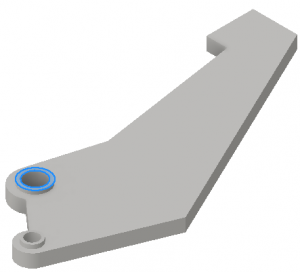

To Apply Constraints

Structural constraints restrict or limit the displacement of the model. Add constraints to mimic environmental conditions. To do so, fix a face, for example, or combine partial constraints on faces, edges, or vertices.

- On the ribbon, Analysis tab Constraints panel, click a structural constraint

Fixed

Apply to a face, edge, or vertex. Removes all degrees of freedom, and prevents the face, edge, or vertex from moving or deforming.

Pin

Apply to cylindrical faces. Prevents the faces from moving or deforming in combinations of radial, axial, or tangential directions

Frictionless

Apply to a flat or cylindrical surface. Prevents the surface from moving or deforming in the normal direction relative to the surface.

or

In the browser, right-click the Constraints node, and click the constraint type.

- In the dialog box, with Location active, select the constraint location..

- For access to other constraint parameters, click (More). The available parameters are based on the constraint type.

Select the appropriate input for the constraint type. You can select more than one input only if the selections are of the same type, such as face, edge, or vertex.

For frictionless constraint

To apply a fixed constraint with non zero displacement:

- Click Use Vector Component

- Select the x, y, or zvector components that define your displacement vector

- Enter the appropriate displacement magnitudes for each vector component.

For Pin constraint

Fix Radial, Axial, or Tangential Direction Cylindrical surfaces cannot move, rotate, or deform radially, axially, or tangentially to the cylinder.

- Click OK.